Thin Film Solar Cells

Solid State Electronics, Department of Engineering Sciences, Uppsala University

Contact: Ass. Prof. Marika Edoff

www.asc.angstrom.uu.se

Thin Film Solar Cell research is an equipment intensive activity and the research group has a state-of-the-art line for fabrication of solar cells and submodules, which is installed in the Solar Cell part of MSL at the Ångström Laboratory. The goal is to obtain solar cells with high efficiency to potentially low cost. Most equipment is group specific and has been developed especially for solar cell research. Solar cells and solar cell materials which have been fabricated are characterized by for example electron microscopes and equipment for X-ray Photoelectron Spectroscopy at MSL. In addition to the material characterization solar cell devices are measured electrically in light and darkness in a dedicated measurement lab facility.

High Quality Cu(In,Ga)Se2 (CIGS) Films for Solar Cells

One important asset of the CIGS material system is the ability to tune the semiconductor properties by changing the Ga/(Ga+In) ratio in the material. A higher gallium content leads to a higher bandgap and thereby a higher voltage in the solar cell device. However, since the bandgap is higher, less light is absorbed and the photoinduced current will be lower as compared to devices with a lower gallium content. The Ga/(Ga+In) ratio can also be changed as a function of the depth of the CIGS material, so called gallium grading. Hence the electrical properties of the material can be optimized. Gallium grading has been studied both by investigating the growth properties, by electrical characterization and by modelling.

HCd-Free Buffer Layers for Thin Film Solar Cells

Conventional CIGS-based solar cells use a CdS buffer layer. This layer is non-optimal, since it absorbs light in the short wavelengths, which is not converted to electric energy. In addition, Cd is a hazardous element, which should be avoided in all products. Cd-free buffer layers are successfully made with atomic layer deposition (ALD), which produces films with conformal coverage similar to CdS layers. Materials which have yielded device results similar to or exceeding ones with CdS are:

• Zn(O,S)

• (Zn,Mg)O

• ZnSnO

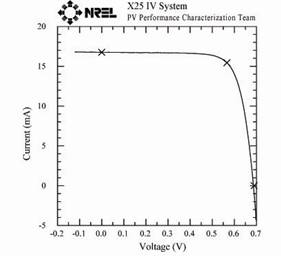

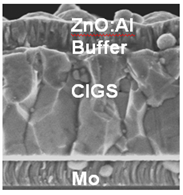

Left: Independently confirmed measurement of an 18.5 % efficient Cd-free device made in the MSL facilities. Middle: An electron microscope cross section of a CIGS-based solar cell with ZnO:Al front contact, buffer layer, CIGS layer and Mo back contact Right: CIGS deposition system in the clean-room.

Solar Cells Made from Abundant Materials: Cu2ZnSn(S,Se)4

In the multiterawatt scale, CIGS constituents may be a limiting factor, therefore research on solar cell materials made from more abundant materials has been initiated. This research area is gaining increasing interest around the world and efficiencies are increasing rapidly. World record efficiencies now exceed 10 % on the small scale cell level. After 1,5 years of research on this emerging material, our best devices are above 3 % efficiency. In the coming year this efficiency will most likely exceed this value with the use of new equipment dedicated to this area of research.

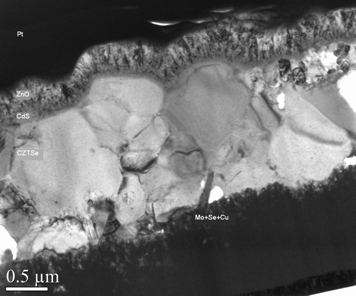

TEM image of a working CZTS solar cell device made by the research group.

Field Testing of Solar Cell Modules

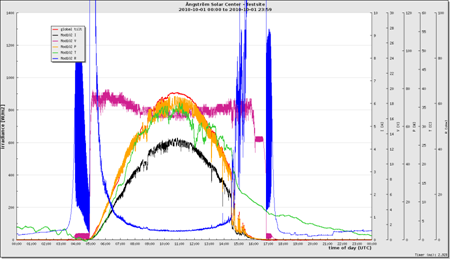

A test site is situated on the roof of the Ångström Laboratory with room for modules and climate monitoring. Modules of different types are mounted and their performance is evaluated using the climate data which are recorded. Measurements are performed every 5 seconds.

Left: Test site on the roof of the Ångström Laboratory. Right: Measurement data from a sunny day.