General information

The Myfab Uppsala analysis laboratory is one of Europes most well equipped facilities for materials analysis. We offer a wide range of equipment for surface imaging, internal structure and compositional analysis.

Fast access to reliable microscopes is important for both materials research and process control. The analysis laboratory is located within the cleanroom laboratory coat area. All of our equipment is located upon a stable foundation, which is required for stable and high resolution investigations. The laboratory is also designed to minimize magnetic stray fields around the instruments. As an internal or external user of the lab you mainly do your own work but it is also possible to hire personnel to help out with your analyses.

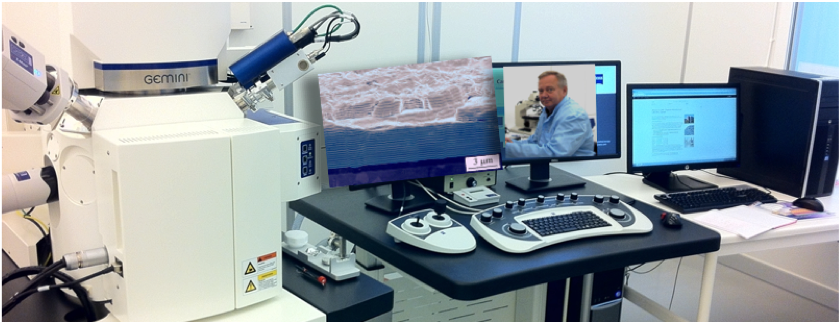

Scanning Electron Microscopy

With an SEM it is possible to study material surfaces of all kinds from low magnification to extreme close-ups and to do element analysis by Energy Dispersive Spectroscopy (EDS). Myfab Uppsala has three SEM which are some of the best electron microscopes on the market. Zeiss Merlin is a high resolution SEM equipped with an Oxford Instruments AZtec EDS and EBSD (Electron Backscatter Diffraction) system. The SEM set-up is completed with two upgraded high resolution systems, LEO 1550 and LEO1530, both equipped with Oxford Instruments AZtec EDS systems.

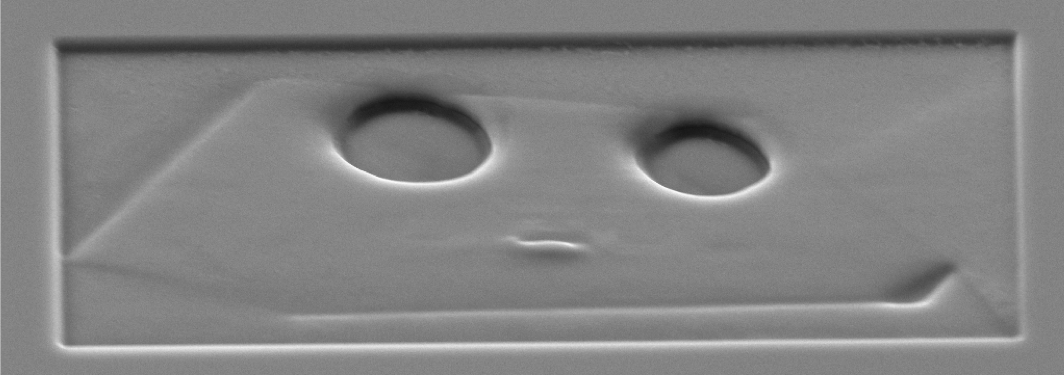

Focused Ion Beam Equipment

The latest contribution to the analysis laboratory is a Zeiss Crossbeam 550 FIB/SEM. This instrument has many applications and great possibilities. The FIB is an SEM, used for imaging, combined with a Ga-ion beam for locally removing or depositing materials. The Crossbeam is also equipped with an AZtec EDS system from Oxford Instruments and an Omniprobe micromanipulator. Applications are for instance local surface structuring, TEM sample preparation, creating cross-sections and serial sectioning for later 3D reconstruction. The second FIB/SEM is an FEI Strata DB235 equipped with a micromanipulator and a cryo stage.

Transmission Electron Microscopy

With a TEM it is possible to reveal the internal microstructure of a sample down to atomic level and in combination analysis techniques determine the elemental composition. Thermo Fisher Scientific Titan Themis 200 is a state-of-the-art 200kV FEG TEM/STEM instrument equipped with a Cs probe corrector and Super-X EDS system. This makes it possible to do high resolution STEM/EDS investigations.

Surface Analysis and Characterization

Surface sensitive elemental composition and chemical binding information from chemical shifts can be determined by Electron Spectroscopy for Chemical Analysis (ESCA) or X-Ray Photoelectron Spectroscopy (XPS), as it is also called. Only the outer most 10-50 Å of the original surface is analysed in one spectrum. For analytical information below the surface, depth profiling with Ar-ions is used. Physical Electronics Quantera II is an instrument with a spacial resolution of 8 µm and an Ar-ion gun for depth profiling. Other techniques used for surface characterization in the lab are light optical microscopy and surface profilometry. Olympus AX70 light microscope with a Nomarski prism and digital camera, Ametek ZYGO nexview is our optical surface profilometer and Park System XE-150 our AFM.

Sample preparation laboratories

Equipment to facilitate the preparation of samples for SEM and TEM are located in two rooms close to the microscopes. A complete line of tools for mechanical preparation from bulk to thin foil including embedding, cutting, grinding, polishing, ultrasonic drill, dimple grinder and ion-milling are available. Also wide cross-sections can be fabricated with broad-ion-beam polishing.